advanced materials Development and analysis

Energy-efficient, mechanically driven nanofiber production for advanced R&D and defense applications

Novel fiber processing

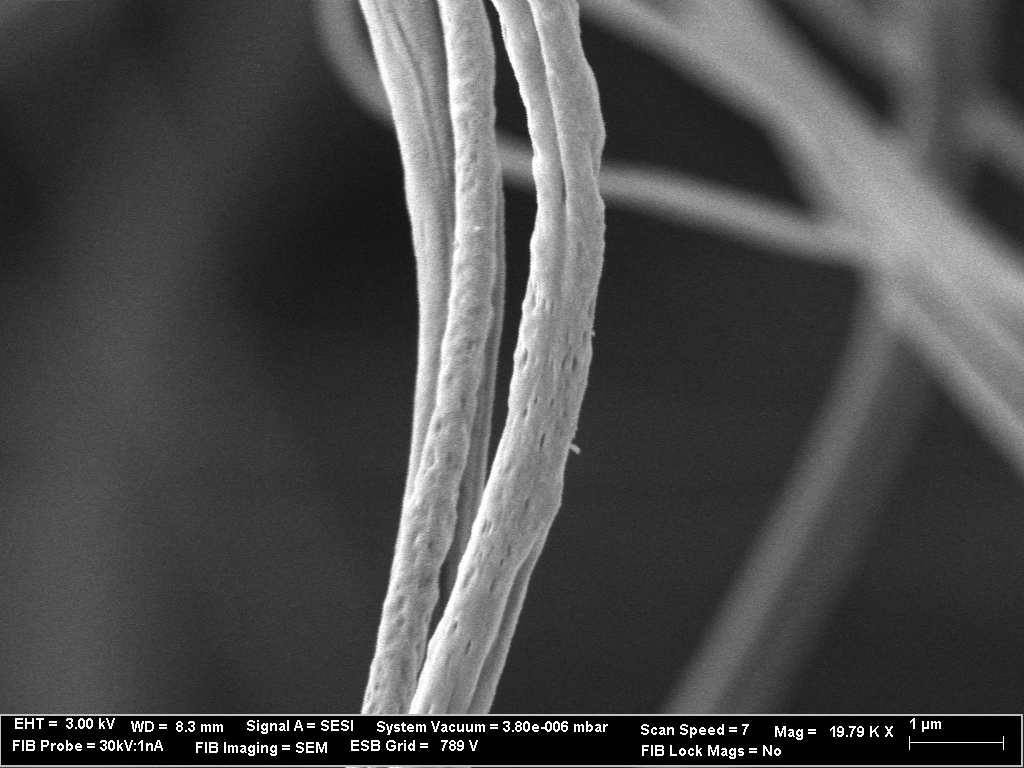

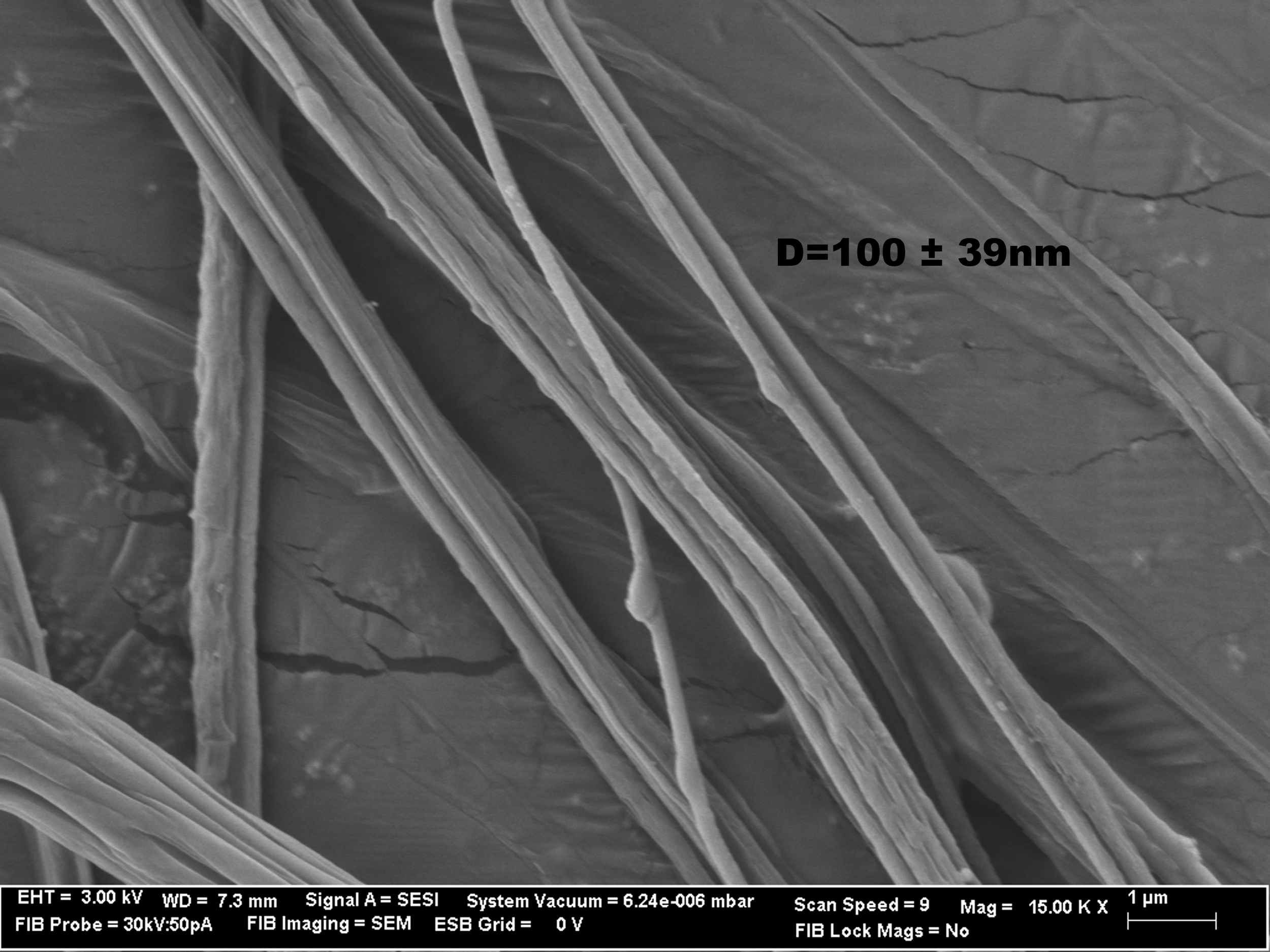

Our mechanical fiber production method produces highly-tunable fiber mats with precise control over alignment, diameter, thickness, and geometry, without thermal stress or restrictive electrical requirements. This allows you to work with polymers that are difficult, sensitive, or impossible to process through electrospinning, melt-spinning, or solvent-heavy methods.

Highly CUSTOM POLYMER PROCESSING FOR strength and performance

Aligned or random nanofibers with full control over diameter, thickness, geometry, and substrate deposition. No thermal history, no complex electrical setup — just clean, precise fibers compatible with biobased and specialty polymers.

FILTRATION

Biomedicine

ELECTRONICS

TEXTILES

services

-

We help develop new fiber-based materials using our mechanical nanofiber process. Our team evaluates polymer compatibility, refines formulations, and produces early prototypes ranging from aligned fibers to uniform mats and complex geometries.

-

We offer detailed analysis of fiber and material performance using our facility’s advanced instrumentation suite. Our testing covers morphology, surface behavior, thermal and chemical properties, and mechanical performance, giving your R&D team clear, decision-ready data.

-

We apply controlled nanofiber coatings directly onto films, textiles, membranes, and composite surfaces. The process supports aligned or random deposition, cross-link–ready surfaces, and tailored performance properties. If your surface needs new functionality, we can put it there.

tell us what you’re building

Our team will review your goals and outline how we can support your material development, testing, or coating work.